Rethink, Reform, Revitalise: Daniel and Team Revital's Journey to Sustainable Innovation

Meet Daniel Foo, a second-year student at the School of Mechanical & Aerospace Engineering (MAE), who is part of a team called Revital. They were among the top 5 winners of the DBS Hungry for Change Challenge, securing a $20,000 grant.

While sustainability is something many of us advocate for, and some may even question how sustainable some of these efforts can be, Daniel and his team have delved deeper into giving a second life to food waste through innovation and technology. Their focus is on creating sustainable food packaging and reducing packaging waste.

Let’s explore further what inspired them to participate in this challenge and more!

Tell us what spurred you to participate in the DBS Hungry for Change Challenge and how you came up with the idea for creating Revital.

We realised that the DBS Hungry for Change Challenge presented an opportunity to develop something tangible, unlike typical hackathons where concepts often lack follow-up. What set us apart was our fresh and open-minded approach. We entered the competition without a predetermined idea, aiming instead to collaborate with established corporations like Koufu. Given Koufu's significant presence in Singapore, our goal was to tailor our concept to their needs. This approach led us to the idea of Revital.

We began by understanding Koufu's needs and conducting extensive research to identify a gap. Our aim was not only to address this gap but also to create a win-win situation for all stakeholders, considering the product's life cycle and its eventual disposal. Our ultimate objective was to achieve 100% valorisation, preventing waste and maximising resource efficiency.

-3.jpg?sfvrsn=e6588f08_1)

What are the roles you and Fernando have played in this interdisciplinary team?

I am responsible for overseeing the entire development of the circular economy to ensure the cup's viability in terms of production, manufacturing, and sustainability at the end of its life cycle. This involves experimenting with potato skins from Koufu, where I was able to make a breakthrough with a method to achieve rigidity and strength through heat moulding at high pressure and temperatures, allowing for the cup's form factor to be achieved.

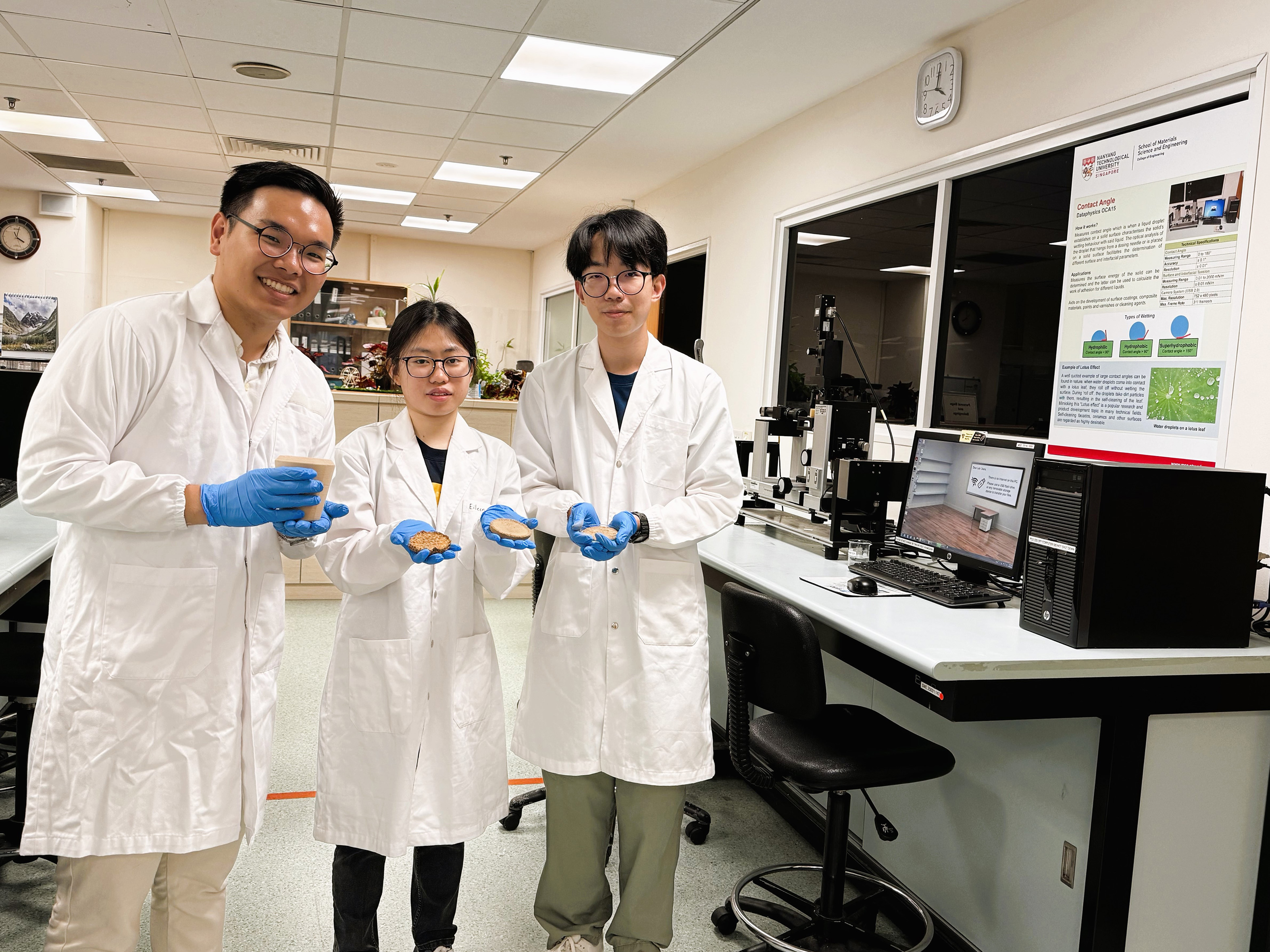

Additionally, I will develop a smart bin that can detect whether the cup is present, as it is integral to our system where users are incentivised to deposit cups into our bins to receive a monetary rebate. Fernando oversees the coating of the cups to ensure they are waterproof, and he conducts testing and experiments in the School of Materials Science and Engineering (MSE) lab.

-4.jpg?sfvrsn=90fff52a_1)

How does your background in MAE contribute to the different stages of this project?

My background in Mechanical and Aerospace Engineering, particularly in the Design stream, played a crucial role in initiating this project. It provided me with a deep understanding of physical constraints, material stress-strain elements, and ergonomics, which are essential for design optimisation and user interaction experiences. Additionally, this knowledge is vital for the development of our manufacturing line, enabling us to produce more cups and bring them to market for pilot implementation.

What opportunities exist for pre-university students to engage with faculty and industry experts who can provide guidance and support throughout their involvement in such projects?

A multitude of opportunities and guidance are available. In the case of MSE, we received support from the Ian Ferguson Innovation Fund to develop our initial product iterations. Initially not intending to create cups, their funding and access to the MSE undergraduate lab were crucial for conducting experiments and finding coating solutions. COE-related projects also benefit from support provided by the Dyson-NTU Studio, offering expertise, funding, and most importantly, workspace for student-initiated projects, facilitating collaboration with team members at NTU.

We received additional support from Prof. Mary Chan and Dr. Guangmin from School of Chemistry, Chemical Engineering and Biotechnology (CCEB), who provided access to her NAFTEC lab for developing our coating. This opportunity was introduced to me by Prof. Holden Li from MAE. Furthermore, I will be producing a prototype mould for my cup using aluminium from the manufacturing lab at the Arc, also under MAE.

Any unique aspects of the project that make it particularly appealing to pre-university students who are passionate about sustainability and making a positive impact on the world?

What distinguishes our project from other sustainable circular economy initiatives is our comprehensive approach to creating systems and subsystems centred around our primary product. We ensure that we incorporate the perspectives of every stakeholder and develop the product with its end-of-life in mind. Rather than allowing the product to degrade and lose its value, we seek opportunities to repurpose it and add value to other industries or sectors.

I believe this framework can guide future developments of sustainable products and ideally, all products in general, considering their lifecycle. Our entire system also addresses consumer behaviour by integrating with the Koufu App. This integration enables us to offer promotions and vouchers, encouraging adoption and fostering a community-wide initiative. We gather inspiration from successful implementations in Germany and Japan, which Singapore currently lacks.

Tell us about the learning from peers from other university and programmes!

I believe it's crucial to involve people whom you know and trust, which is why I initially reached out to my friends. However, it's equally important to have a diverse team with individuals having various strengths and academic backgrounds. This diversity allows for a multi-disciplinary approach, enabling the development of not only the product but the entire system, including managing stakeholder expectations and creating promotion mechanisms.

One challenge I encountered was coordinating meetings due to timing clashes. Despite this, we made efforts to meet online and maintain accountability for each task. Another important aspect of team collaboration is ensuring everyone is aligned at every step. Our concept had to pivot multiple times, and accommodating everyone's opinions, given the variety of backgrounds, was extremely important.

The project, Revital, is currently focused on developing and implementing its end-product. The team hopes to raise awareness within the NTU ecosystem to establish a stronger network for our circular economy and sustainability system.

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)