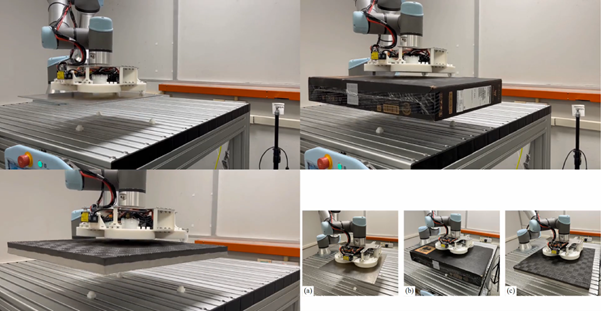

QuadGripper with Cooperative Suction Mechanism and Closed-Loop Control Method for Minimised-Contact Gripping

Synopsis

The QuadGripper is an innovative device designed for lifting and manipulating objects with minimal contact and damage. Featuring four suction units capable of generating both force and torque, this technology has the potential to revolutionise material handling, particularly for delicate surfaces like silicon wafers, solar cells, and glass.

Opportunity

The QuadGripper presents a novel approach to material handling, leveraging four suction units to lift and manipulate objects with minimal contact, reducing the risk of surface flaws. This can significantly enhance production quality and efficiency while lowering maintenance costs and labour. Applicable in various automated production lines, including electronics, automotive, aerospace, and biomedical industries, the QuadGripper can perform complex tasks such as picking, placing, orienting, and inspecting. Its adaptability to different shapes and sizes of objects, facilitated by the cooperative suction mechanism and closed-loop control method, makes it a versatile and innovative device solution for modern material-handling systems.

Technology

The QuadGripper comprises four suction units attached to a frame, generating both force and torque on an object’s surface without direct contact. This cooperative suction mechanism adjusts force and torque according to the object’s shape and weight. Additionally, a closed-loop control method monitors and corrects the object’s position by altering the inputs to the suction units. This design allows the QuadGripper to handle delicate surfaces, preventing surface flaws. As an end-effector for manipulators in automated production lines, the QuadGripper offers a flexible and efficient solution for material handling.

Figure 1: Application of Quadgripper in action carrying various objects.

Applications & Advantages

- The QuadGripper can lift and manipulate objects with minimal contact and damage, using four suction units that generate both force and torque.

- It handles delicate components, such as silicon wafers, solar cells, and glass, without causing surface flaws.

- It reduces maintenance costs and labour by eliminating the need for mechanical parts or lubrication.

- It is applicable in various automated production lines, including electronics, automotive, aerospace, and biomedical industries, and can perform complex tasks such as picking, placing, orienting, and inspecting.

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)

7e6fdc03-9018-4d08-9a98-8a21acbc37ba.tmb-mega-menu.jpg?Culture=en&sfvrsn=7deaf618_1)

.tmb-listing.jpg?Culture=en&sfvrsn=b5366f51_1)

.tmb-listing.jpg?Culture=en&sfvrsn=3b74ec1c_1)