Printed Porous Elastomeric Conductor for Stretchable Electronics

Synopsis

This method is used for creating printed stretchable and non-stretchable silver flake conductors (Ag electrodes). These printed porous elastomeric conductors (PPECs) find applications in wearable electronics, biomedical devices and energy storage systems due to their flexibility and conductivity.

Opportunity

The invention relates to a method to fabricate printed stretchable and non-stretchable silver flake conductors (Ag electrodes).

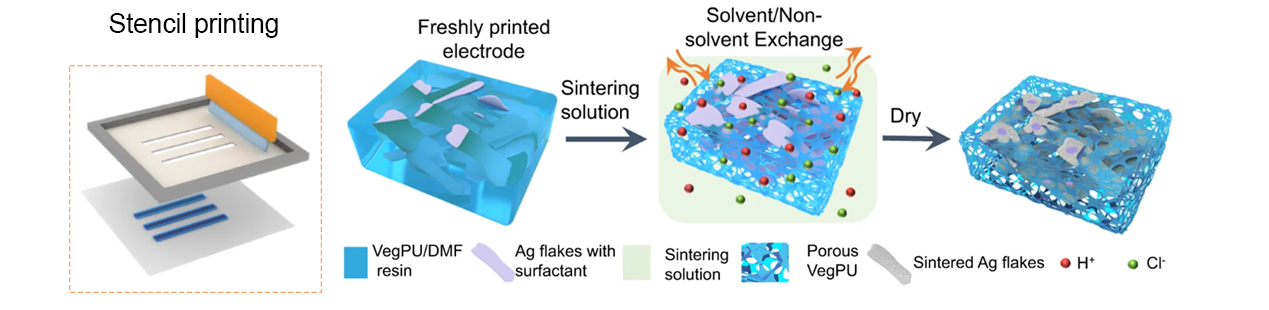

Printed porous elastomeric conductors (PPECs) are a type of stretchable electronic material that can be used in a variety of applications. They are made by printing a conductive material, such as silver or carbon, onto an elastomeric substrate, which is a flexible and stretchable material.

Technology

Silver flake presents itself as an exceptionally promising conductive filler for the fabrication of expansive devices, thanks to its ability to be manufactured on a large scale, its stability, and its remarkable conductivity. However, attaining an optimal equilibrium between conductivity and stretchability in printed conductors proves to be a formidable task. While a heightened concentration of conductive fillers enhances the pathways for electron transfer, it simultaneously undermines the material's ability to resist cracking when subjected to stretching forces. This challenge has been successfully tackled through the development of in-situ silver nanoparticles that align themselves along the direction of strain, thereby effectively mitigating the formation of cracks.

Figure 1: Stencil printing to create porous elastomeric conductors for stretchable electronics.

Applications & Advantages

Some potential applications for PPECs include:

- Wearable electronics, such as fitness trackers and smart clothing.

- Biomedical devices, such as stretchable sensors for monitoring heart rate or skin conductance.

- Energy storage devices, such as stretchable batteries and supercapacitors.

Printed porous elastomeric conductors have several advantages over traditional electronic materials, including:

- Highly stretchable and can be stretched to over 700% of their original length without losing conductivity.

- Can be printed using inexpensive and scalable techniques, such as screen printing or inkjet printing.

- Can be integrated into a variety of devices, including sensors, actuators, and energy storage devices.

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)

7e6fdc03-9018-4d08-9a98-8a21acbc37ba.tmb-mega-menu.jpg?Culture=en&sfvrsn=7deaf618_1)

.tmb-listing.jpg?Culture=en&sfvrsn=3b74ec1c_1)

-and-the-coated-wood-(ntu-singapore).tmb-listing.jpg?Culture=en&sfvrsn=624bb80c_1)