NTU Singapore scientists develop smart technology for synchronised 3D printing of concrete

Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a technology where two robots can work in unison to 3D-print a concrete structure.

This method of concurrent 3D-printing, known as swarm printing, paves the way for a team of mobile robots to print even bigger structures in future.

Developed by Assistant Professor Pham Quang Cuong and his team at NTU’s Singapore Centre for 3D Printing, this new multi-robot technology was published in Automation in Construction, a top tier journal for civil engineering. The NTU scientist was also behind the Ikea Bot earlier this year where two robots assembled an Ikea chair in 8 min 55s.

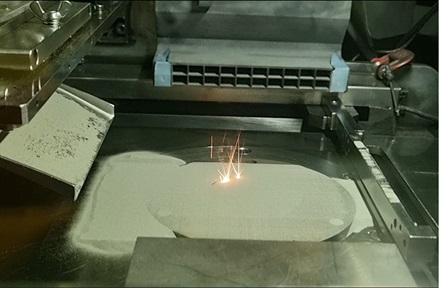

Using a specially formulated cement mix suitable for 3-D printing, this new development will allow for unique concrete designs currently not possible with conventional casting. Structures can also be produced on demand and in a much shorter period.

Having multiple mobile robots that can 3D print in sync means large structures like architectural features and specially-designed facades can be printed anywhere as long as there is enough space for the robots to move around the work site.

The NTU robots 3D-printed a concrete structure measuring 1.86m x 0.46m x 0.13m in eight minutes. It took two days to harden and one week for it to achieve its full strength before it was ready for installation.

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)