Reducing carbon emissions from waste disposal

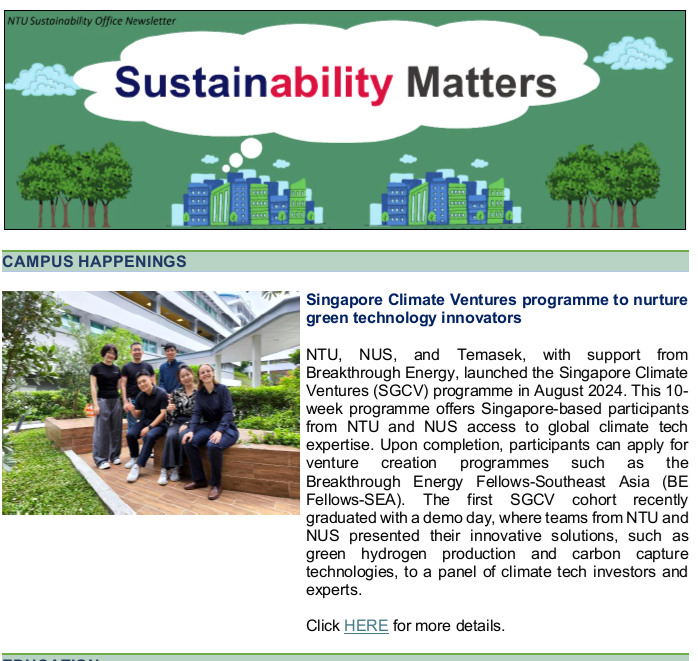

NTU researchers construct a model to find out how to make waste incineration more environmentally friendly.

Incinerating solid waste is an important waste management strategy that greatly reduces the amount of non-recyclable solid waste and generates energy at the same time. However, burning waste produces carbon dioxide that contributes to greenhouse gas emissions and climate change.

One method to minimise carbon dioxide emissions from incineration plants is to use calcium oxide to capture the emissions. In this process known as calcium looping, calcium oxide reacts with carbon dioxide to form calcium carbonate when heated to temperatures of around 650 degrees Celsius. The reaction is reversible, and carbon dioxide is released from the calcium carbonate at higher temperatures of about 900 degrees Celsius. The released carbon dioxide can then be purified for other purposes.

However, calcium looping is energy-intensive and expensive. To evaluate its feasibility in incineration plants, researchers led by Assoc Prof Grzegorz Lisak of NTU’s School of Civil and Environmental Engineering constructed a detailed model that accounts for the different variables in calcium looping.

From their model, the scientists found that using fuels produced from recovered waste for heating was the most economical and that leveraging waste-derived calcium sources, such as incineration ash, can further reduce the overall cost of this technology. Carbon credits and taxation that incentivise negative emissions also make calcium looping more economically viable.

Find out more in “A techno-economic assessment of the reutilisation of municipal solid waste incineration ash for CO2 capture from incineration flue gases by calcium looping”, published in Chemical Engineering Journal(2023), DOI: 10.1016/j.cej.2023.142567.

The article appeared first in NTU's research and innovation magazine Pushing Frontiers (issue #24, October 2024).

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)

7e6fdc03-9018-4d08-9a98-8a21acbc37ba.tmb-mega-menu.jpg?Culture=en&sfvrsn=7deaf618_1)