A Hydrogel Composite

Synopsis

The global 3D printing market is poised to reach $56.1 billion by 2026, growing at a CAGR of 23.5%. Tissue engineering faces challenges in creating vascular network structures. This invention presents a hydrogel composite and shaping method for synthesising vasculature-like structures via 3D printing, promising advancements in tissue engineering and regenerative medicine.

Opportunity

The global market for 3D printing is expected to grow from $19.5 billion in 2021 to $56.1 billion by 2026, at a CAGR of 23.5%. A major challenge in tissue engineering is creating vascular network structures, especially for tissues thicker than approximately 200 μm. Vascular structures are typically multi-layered, hollow, complex with varying diameters, making them difficult to replicate using materials similar to native vessels, such as hydrogels. Insufficient vascularisation can lead to hypoxia and the formation of non-uniform tissue structures, limiting the effectiveness of engineered tissues.

Technology

This invention presents a hydrogel composite and a method for shaping it into a 3D network, specifically tailored for tissue engineering applications. The enhanced hydrogel composite and shaping technique enable the synthesis of vasculature-like structures using 3D printing, advancing the field of biofabrication.

The bio-ink hydrogel exhibits exceptional printability and mechanical strength, allowing for the creation of intricate biological structures for various biomedical applications. Its robust mechanical properties render it suitable for placement in a bioreactor, where further tissue maturation can occur in vitro prior to implantation.

These attributes are crucial for manufacturing cellularised scaffolds, offering a platform for developing functional tissues and organs. By providing a versatile and reliable method for fabricating complex biological structures, this innovation has the potential to revolutionise tissue engineering and regenerative medicine, paving the way for personalised therapeutic solutions and improved patient outcomes.

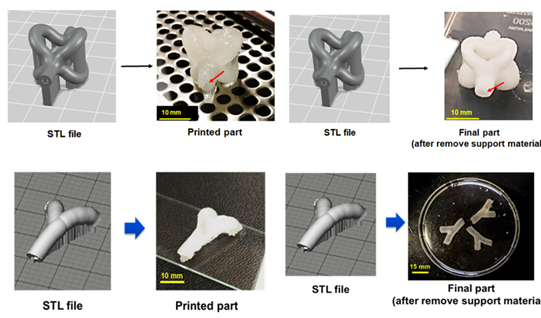

Figure 1: A new formulation of hydrogel with high fidelity enables 3D bioprinting of tissue and organ.

Applications & Advantages

Main application areas include tissue engineering, 3D printing and bioprinting tissues.

Advantages:

- High printability

- High mechanical strength

- Capability to synthesise vasculature-like structures

.tmb-listing.jpg?Culture=en&sfvrsn=a0428bd8_1)

-with-those-from-other-fungi.tmb-listing.jpg?Culture=en&sfvrsn=3025740f_1)