A Colorimetric Sensing System for Food and Beverage Volatile Organic Compound (VOC) Analysis

Synopsis

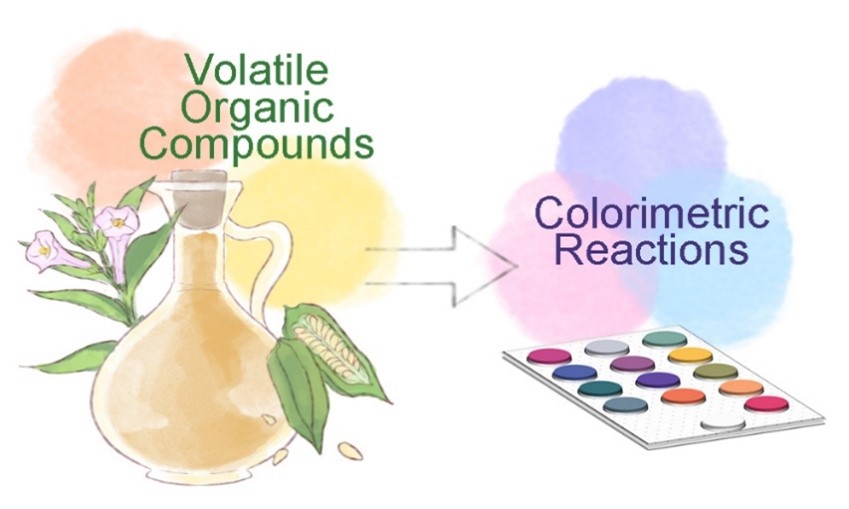

This colorimetric volatile organic compound (VOC) sensing system is designed for analysing edible plant oils to reveal information about oil processing technology, raw materials, adulteration and freshness. It can also detect VOCs released by various products, including vinegar, soy sauce, coffee and nail polish remover, by exhibiting colour changes.

Opportunity

Flavour is an important quality indicator for many food and beverage products, largely determined by VOCs. Traditionally, flavour is evaluated through human sensory analysis, which, despite its value, suffers from subjectivity and the high cost of training evaluators. Laboratory methods, such as gas chromatography, are also limited by cost and complexity. A colorimetric sensor offers a simple, rapid and cost-effective alternative, converting information on sample VOCs into a colour fingerprint for easy interpretation, using indicators that can chemically react with target VOCs.

Technology

This invention features a colorimetric VOC sensing system, consisting of a 14-unit paper-based sensor and a self-built sensing device. It utilises three types of colorimetric indicators: pH indicators, aldehyde-sensitive indicators and solvatochromic dyes, which provide basic information on the chemical composition of VOCs emitted by a sample. The system is designed for analysing food and beverage products, particularly edible plant oils, and has been validated with chemical standards and actual product samples. Preliminary results suggest that this system can generate a colorimetric fingerprint, offering a simple and rapid way to visualise the VOC profile of a given sample.

Figure 1: A colorimetric sensing system for volatile organic compounds (VOCs).

Applications & Advantages

Main application areas include quality control, for example the detection of changes in VOC profile due to various factors, such as raw material, processing technology, adulteration and degradation. Also applicable in product development, competitor analysis and freshness evaluation.

Advantages:

- Simple experimental procedure—no heating required unlike traditional methods

- Colour changes are observable with the naked eye

- Offers a rapid and cost-effective alternative to complex laboratory methods

.tmb-listing.jpg?Culture=en&sfvrsn=b5366f51_1)