Enhanced Carbonation and Mechanical Performance of Bacteria-Based RMC Paste

Synopsis

This invention presents an innovative bacteria-based method that utilises ureolytic bacteria, urea, and nutrients to release CO2 internally for carbonating reactive magnesia cement (RMC)-based systems, enhancing their strength and durability. This sustainable and efficient alternative to traditional methods has the potential to revolutionise the construction industry, making it ideal for applications in buildings, bridges, and roads.

Opportunity

The construction industry is a significant contributor to greenhouse gas emissions, primarily due to cement production. However, recent advancements in biotechnology have led to the development of microbial-based carbonation methods that can reduce the environmental impact of traditional carbonation methods. With a projected market size of US$12.3 billion by 2025, these sustainable carbonation methods have the potential to revolutionise the construction industry by offering a greener and more efficient alternative to conventional practices.

Technology

This invention introduces a bacteria-based method for providing CO2 for the carbonation of RMC-based systems. The method employs ureolytic bacteria, urea and nutrients to release CO2 through hydrolysis, which improves the strength and durability of RMC-based systems. This technological advancement provides a sustainable and efficient method for carbonating RMC-based systems, enhancing their mechanical performance and extending their lifespan.

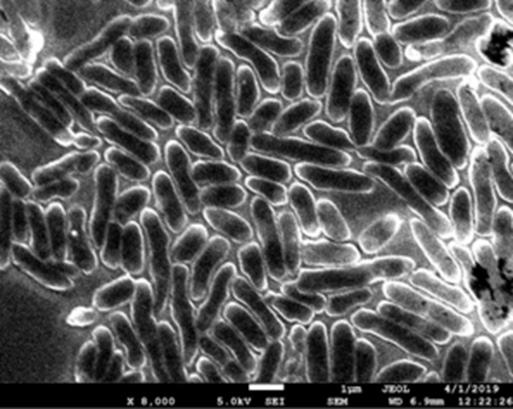

Figure 1: SEM morphology image of the bacteria culture used in cement paste.

Applications & Advantages

Main application areas include the construction of buildings, bridges and roads.

Advantages:

- Utilises bacteria-based carbonation, significantly reducing the environmental impact compared to traditional methods

- Improves the strength and durability of RMC

- Reduces greenhouse gas emissions associated with cement production

.tmb-listing.jpg?Culture=en&sfvrsn=55153609_1)

.tmb-listing.jpg?Culture=en&sfvrsn=b5366f51_1)