Flexible Graphical User Interface for AGV Fleet Management Simulation Software

Synopsis

This patented automated guided vehicle (AGV) fleet management simulation software integrates with the Internet-of-Things (IoT), uses machine learning for route optimisation, offers augmented reality for immersive experiences and anticipates maintenance needs. It provides detailed analytics, supports collaborative design and is customisable and scalable for various industries, enhancing efficiency and decision-making.

Opportunity

This patented user interface for AGV fleet management simulation software offers diverse opportunities for innovation and improvement. Integration with IoT devices enables real-time data collection, improving simulation accuracy. Machine learning algorithms optimise AGV routes based on historical data, improving overall efficiency. Augmented reality features offer an immersive user experience, enabling real-time visualisation of AGV movements within the factory. Predictive maintenance capabilities anticipate potential issues, minimising downtime.

The system’s enhanced analytics and reporting provide comprehensive insights into key performance indicators, facilitating informed decision-making. A collaborative simulation environment fosters teamwork in factory layout design and analysis. Adaptability for various industries broadens its applicability, while customisation and scalability features allow users to tailor simulations to specific needs.

The potential integration of artificial intelligence (AI) enables collaborative decision-making, providing AI-driven suggestions for optimising factory layouts and predicting bottlenecks. Exploring a cloud-based platform enhances accessibility, allowing users to run simulations from anywhere. Together, these opportunities position the patented software as a versatile, efficient and adaptable solution for AGV fleet management and related industries.

Technology

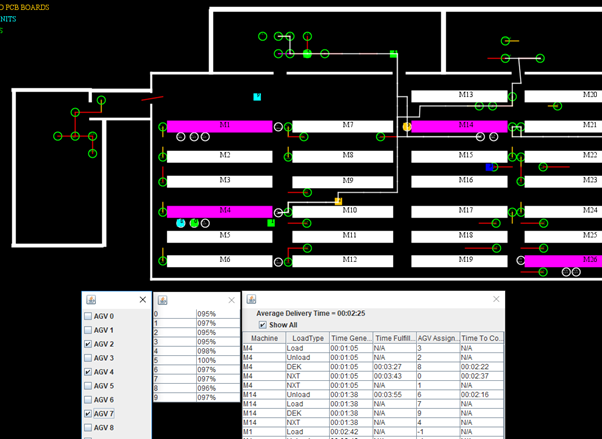

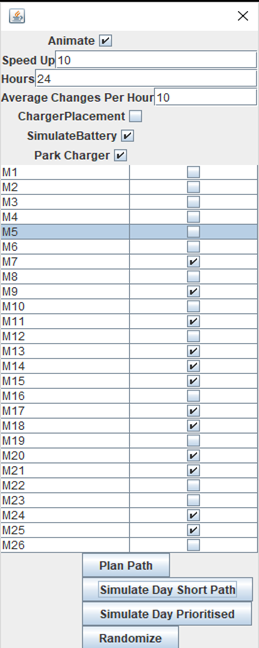

The graphical interface is a versatile component of the AGV fleet management simulation software. It allows users to configure factory layouts, integrate AGV paths, establish production lines, and define charging stations and loading/unloading ports. These configurations can be seamlessly imported into the AGV fleet management software for simulations and in-depth analysis, enhancing operational efficiency.

Figure 1: Simulation software layout.

Figure 2: Customised configuration for efficiency performance comparison.

Applications & Advantages

Applications

- Manufacturing: Optimise factory layouts and production processes.

- Logistics: Streamline material handling and warehouse operations.

- Distribution Centres: Enhance efficiency in goods movement and storage.

- Automotive Industry: Improve assembly line operations and material flow.

- E-commerce: Optimise order fulfilment and inventory management.

Advantages

- Enhances decision-making with live data.

- Minimises downtime through proactive maintenance.

- Adapts to varying operational sizes and complexities.

- Facilitates teamwork in designing and analysing simulations.

- Applicable across industries for diverse operational needs.

.tmb-listing.jpg?Culture=en&sfvrsn=3b74ec1c_1)

.tmb-listing.jpg?Culture=en&sfvrsn=414f0d90_1)