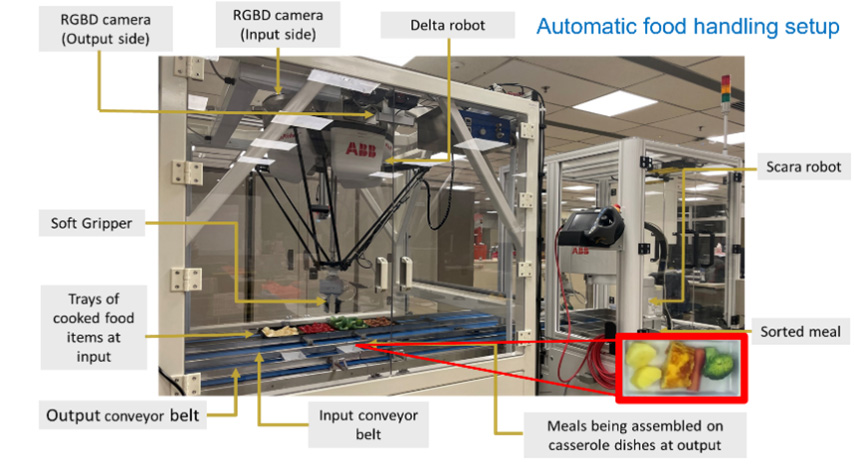

Robotic Meal-Assembly Systems and Robotic Methods for Real-Time Object Pose Estimation of High-Resemblance Random Food Items

Synopsis

This integrated system combines vision detection, motion planning and a soft gripper mechanism to handle food items efficiently. Using adaptive food recognition, it groups visually diverse items into the same category, accommodating natural variations and enhancing efficiency in food handling and assembly.

Opportunity

The rising costs of labour and the need for enhanced hygiene in food processing are driving demand for automation in the food industry. This system minimises human involvement, reducing labour expenses and potential contamination risks. It ensures consistent product quality round-the-clock, with real-time adjustments based on specific onsite requirements. Versatile enough for various assembly systems, including warehouse packaging, it adeptly handles irregularly shaped items, ensuring precision in sorting and packaging.

Technology

This innovative system integrates vision detection, motion planning and a soft gripper to create a cohesive pipeline for food arrangement and handling. Advanced machine learning enables adaptive food recognition, classifying foods with subtle visual differences into the same category. The closed-loop self-correction mechanism ensures meal assembly accuracy, correcting any omissions in real-time. The system’s multi-gripper compatibility allows for easy interchange based on food type, without extensive recalibration.

Figure 1: Considering the huge labour cost in many food production scenarios, our robotic-assisted food handling system under the line production environment was proposed to enhance the hygiene standards, enforce quality consistency, and reduce labour costs

Applications & Advantages

Applications:

- Automated meal assembly: For cafeterias, airline catering and pre-packaged meal services.

- Quality control: Ensures consistent food item placement and visual standards.

- Training: Demonstrates automation potential in culinary institutions.

- Custom meal services: Personalised meal kits tailored to customer specifications.

Advantages:

- Adapts to subtle food differences for precise recognition.

- Reduces labour costs and minimises waste.

- Identifies and rectifies errors in real-time.

- Adaptable to varied operations and food items.

- Capable of accommodating new industry requirements.