Computer Interface for Automated Vehicle Fleet Simulation in System Integration and Manufacturing Operation

Synopsis

This industrial logistic automation framework leverages Industry 4.0's shift towards adaptable logistic solutions. It provides a flexible, modular approach for integrating diverse AGVs, featuring anti-interference communication, a multi-level architecture for efficient task and path management and optimised battery recharge. This ensures operational efficiency and adaptability in dynamic manufacturing environments.

Opportunity

As manufacturing rapidly transitions into the Industry 4.0 era, there is a growing demand for adaptable and efficient logistic automation solutions. This industrial logistic automation framework meets this demand by offering a flexible, modular approach that accommodates diverse AGVs. With anti-interference wireless communication and a multi-level computing architecture, the framework optimises task assignment, path planning and battery recharge management. This adaptability not only improves operational efficiency but also presents a strategic advantage in dynamic and unpredictable factory settings.

Technology

This system represents a shift from conventional centralised control systems in logistics. It integrates AGVs of different brands and types, featuring the TruePath Kit—a universal sensor unit for local processing of environmental information for AGV perception, planning and motion control. Anti-interference wireless communication, multi-level computers and modular adaptability address the limitations of traditional systems. The AGV fleet management system (AGVFMS) optimises task assignment, path planning and battery recharge management, ensuring operational efficiency in dynamic manufacturing environments. The framework's adaptability positions it as a cornerstone for agile and cost-effective logistics automation.

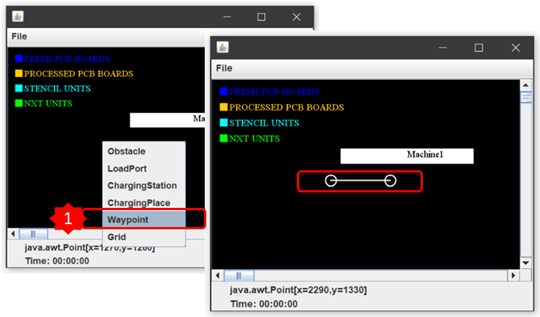

Figure 1: Computer interface illustrating how waypoint and links can be added.

Applications & Advantages

Applications:

- Manufacturing Logistics: Ideal for diverse material handling tasks with a fleet of AGVs.

- Industry 4.0 Integration: Adaptable to changes in manufacturing processes and business requirements.

- Dynamic Environment Operations: Ensures continual AGV operation in unpredictable and dynamic factory settings.

Advantages:

- Integrates AGVs of varying brands and functions for flexibility.

- Prioritises AGV tasks based on energy levels, ensuring optimal operation.

- A* algorithm and hybrid strategy for collision avoidance and dynamic obstacle handling.

- Reduces factory delays by optimising recharge sequence and population.

.tmb-listing.jpg?Culture=en&sfvrsn=3b74ec1c_1)

.tmb-listing.jpg?Culture=en&sfvrsn=414f0d90_1)