Methods of Stereolithography 3D Printing of Silicon Nitride Ceramics with High Strength and High Thermal Conductivity

Synopsis

This invention enables the 3D printing of silicon nitride ceramics via stereolithography (SLA), overcoming the limitations of traditional manufacturing. With tunable viscosity and enhanced resolution, the resulting ceramics possess properties comparable to conventionally made silicon nitride.

Opportunity

Silicon nitride (Si3N4) ceramics are highly valued for applications in extreme environments due to their high mechanical strength, thermal shock resistance and high-temperature creep resistance. These properties make Si3N4 ideal for automotive engine parts, ball bearings, heat exchangers and structural supports for space telescopes. However, traditional manufacturing methods struggle to produce complex structures with fine features and suffer from long processing cycles and high costs. Additive manufacturing (AM) or 3D printing can address these drawbacks.

Technology

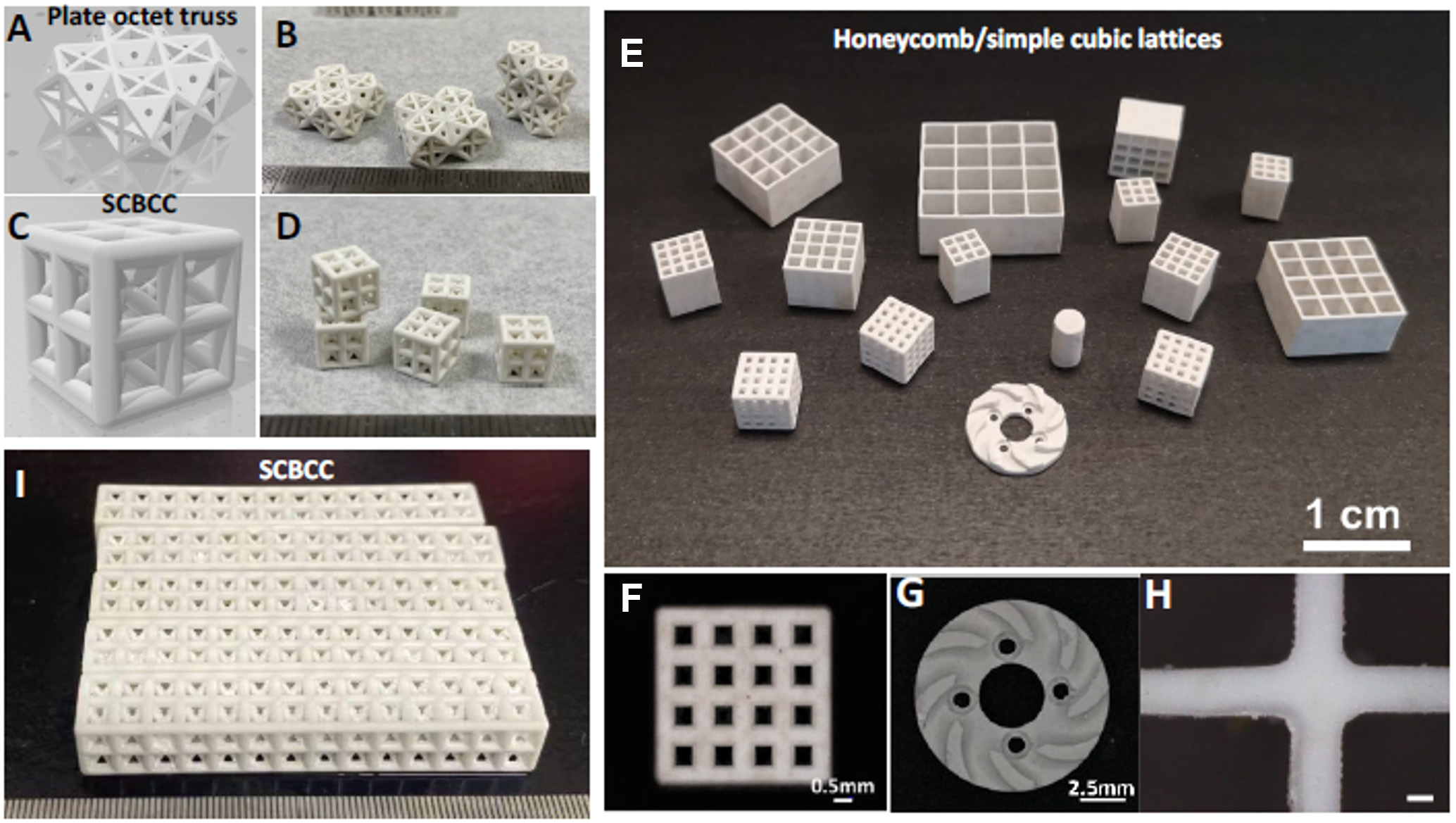

This invention involves paste compositions for printing Si3N4 ceramics suitable for SLA 3D printing. The method overcomes traditional manufacturing limitations by enabling the production of highly complex structures with fine features. The technology allows for the tuning of paste velocity and enhancement of printing resolution, yielding Si3N4 ceramics with comparable mechanical properties and thermal conductivity as conventionally manufactured counterparts. Using varying sintering additives, solid loads, dispersants, photo-initiators, the depth of the cure could be manipulated. By employing low-UV absorbance sintering aids, tailored sintering profiles and carbothermal treatment to minimise oxygen content and promote in-situ formation of sintering aids (MgSiN2), high thermal conductivity Si3N4 ceramics are formed.

Figure 1: (A,C) Digital model and (B,D, E, F-I) photos of the complex shaped Si3N4 ceramics printed and sintered in this work. The ruler showing in (B,D,I) has the smallest scale of 1 mm.

Applications & Advantages

Applications:

- Cutting tools

- Ball bearings and rollers

- Turbochargers and engine components

- Heat exchangers

- Semiconductor manufacturing

- Medical implants

- Metal casting

- Electronics

- Aerospace components

- Renewable energy technologies

Properties:

- Can withstand extreme temperatures (>1000°C).

- High strength, hardness, and toughness.

- Resistant to thermal shock and cycling.

- Suitable for abrasive conditions.

- Resistant to various chemicals.

- Ideal for electronics and semiconductors.

- Suitable for sliding or rotating components.

- Well-tolerated by biological systems.

.tmb-listing.jpg?Culture=en&sfvrsn=b5366f51_1)