Beating air pollution and bacteria with nanoparticles

Prof Lam Yeng Ming and Prof Liu Zheng use silk proteins and tiny particles to make air filters.

.jpg?sfvrsn=29c7e020_1)

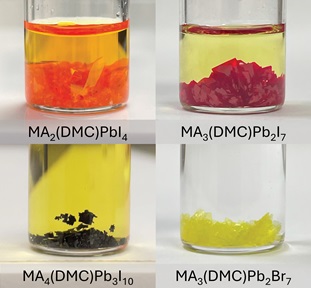

When cuprous oxide particles – pictured above under a field-emission scanning electron microscope – were coated on fabrics, the particles had an average bacterium killing efficiency of over 93%. Credit: NTU.

By Lam Yeng Ming and Liu Zheng

Air pollution, particularly in cities, is harmful to human health. Polluted air contains microscopic particles called PM2.5 that can cause lung and heart diseases. Bacteria in the air can contribute to disease too.

Highly efficient air filters can alleviate these urban challenges, but many traditional filters cannot remove PM2.5 particles that are 2.5 micrometres in size – about 40 times smaller than the diameter of a strand of hair. These filters are also not able to kill airborne germs like bacteria that can be smaller than 1 micrometre.

To address these issues, we explored and combined two approaches to develop an air filter that is mechanically stronger, biodegradable and highly effective at filtering out air pollutants and eliminating bacteria.

ANTIBACTERIAL COPPER

Our first approach is to use nanoparticles made of copper, which has long been known to have antibacterial properties.

In fact, the ancient Greeks and Aztecs used mixtures or compounds containing copper for wound treatment. Studies have shown that some forms of copper nanoparticles are safe for human use and, in some cases, even beneficial for open wounds. Other research suggests that copper nanoparticles can destroy viruses too.

We studied nanoparticles made of a copper compound, called cuprous oxide, about 150 nanometres in diameter, as well as smaller copper metal particles at 50 nanometres.

We spray-coated them separately onto fabrics commonly used to make face masks and filters for air purification such as in ventilation systems in hospitals and aeroplanes.

The bacteria-killing ability of the coated fabrics was tested using antibiotic-resistant bacterial strains of Klebsiella pneumoniae and Pseudomonas aeruginosa, which can cause pneumonia and blood infections respectively.

Fabrics coated with cuprous oxide nanoparticles had an average bacterium killing efficiency of over 93%. For fabrics with a layer of metallic copper nanoparticles, the efficiency was more than 84%. In all instances, bacteria were eliminated within 45 seconds.

We observed that the nanoparticles produced free radicals and unstable molecules that can damage cells, and found damaged bacteria DNA. These findings suggest that cuprous oxide and metallic copper nanoparticles induced the formation of free radicals that cause oxidative damage to bacteria and kill them. Another possibility is that electrostatic forces between the bacteria and the nanoparticles stretched and disrupted the bacteria’s membranes, thereby destroying them.

Further tests showed that after six days of exposure to K. pneumoniae, the cuprous oxide-coated fabrics had a sustained ability to kill the bacteria.

.jpg?sfvrsn=c089b6e0_1)

Field-emission scanning electron microscope image showing damaged K. pneumoniaebacteria on fabric, likely compromised by the coating of cuprous oxide particles. Credit: NTU.

ELECTROSTATIC ATTRACTION

Our second approach to improving air filtration involves mixing electrostatic nanoparticles with silk fibroin, a protein extracted from silkworm cocoons.

The nanoparticles are made from lanthanum nitrate and 300 times smaller than the width of a strand of hair. Lanthanum nitrate is used to speed up chemical reactions in industrial processes. It also produces an electrostatic effect that can better attract and trap tiny particles when squeezed or pressed. We added these nanoparticles to silk proteins to create nanosized fibres for air filtration.

Testing the strength of this nanoparticle-silk protein filter, we found that its breaking strain – how much the material can stretch before it breaks – was 2.1 times higher than that of a filter made purely from silk proteins.

In terms of performance, our filter reduced the concentration of PM2.5 particles simulated using cigarette smoke by 92%. It also filtered out 98% of Escherichia coli and Staphylococcus aureus, bacteria that cause gut and skin infections respectively.

To further improve our filter, we added nanosized graphitic carbon nitride that is known to kill bacteria under sunlight. The filter neutralised 99% of E. coli trapped in it after exposure to ultraviolet light, which is found in sunlight, for 120 minutes. The mechanical strength of this filter was also comparable to our original filter without graphitic carbon nitride.

Both versions of our silk protein filter are biodegradable, breaking down after being buried in the soil for nine days. While the nanosized lanthanum nitrate and graphitic carbon nitride did not easily degrade, the quantities used were low, and they are considered eco-friendly and not harmful to living things.

The commercial silk fibroin protein filter with lanthanum nitrate and cuprous oxide nanoparticles, co-developed by NTU and Renmin University of China, was able to remove 99.9% of bacteria and tiny particles of different sizes in polluted air. Credit: NTU.

DOUBLE-LAYER PROTECTION

We combined both approaches to develop an air filter with a double layer of protection.

The filter was made of biodegradable silk proteins, as well as lanthanum nitrate nanoparticles which help attract and trap air pollutants and bacteria through an electrostatic effect. The filter was also coated with bacteria-killing cuprous oxide nanoparticles.

During testing, the refined air filter removed 99.9% of bacteria and tiny particles of different sizes in polluted air – from 0.3 micrometres, which is smaller than PM2.5, to 10 micrometres. The filter also killed 99.9% of multi-drug resistant bacteria in 45 seconds.

We have since commercialised our air filter and it is being used by organisations in China to filter out bacteria in hospitals. In other settings, the filter has been used to remove tiny air pollutants.

---

Prof Lam Yeng Ming is the Chair of NTU’s School of Materials Science and Engineering (MSE) and President’s Chair in Materials Science and Engineering. Her research aims to understand and design functional nanomaterials with novel structures that have applications in sustainable energy, food production and environment remediation.

Prof Liu Zheng, President’s Chair in Materials Science and Engineering at MSE, works on the synthesis, engineering and application of ultra-thin 2D materials. His research has resulted in novel materials for high-performance electric devices, electrocatalysts and photocatalysts.

Details of the research presented here can be found in Chemical Engineering Journal (2021), DOI: 10.1016/j.cej.2021.131947; and ACS Applied Nano Materials (2022), DOI: 10.1021/acsanm.2c02736.

The article appeared first in NTU's research & innovation magazine Pushing Frontiers (issue #24, October 2024).

.tmb-listing.jpg?Culture=en&sfvrsn=55153609_1)