Getting a grip on humanoid hands

Created from spider silk, fibres resembling human tendons help to turn robotic hands into prosthetics.

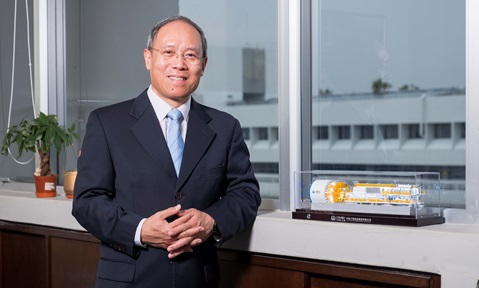

A 3D-printed humanoid robotic hand incorporating an electro-tendon made of spider silk and a pressure sensor mounted on the index finger. Credit: Pan Liang/Chen Xiaodong.

A 3D-printed humanoid robotic hand incorporating an electro-tendon made of spider silk and a pressure sensor mounted on the index finger. Credit: Pan Liang/Chen Xiaodong.

For humanoid robotic hands to serve as prosthetics, they must rely on a tendon-driven transmission system to transmit an actuation force to the joints. However, currently available tendon fibres have low toughness and stretchability, and many of them are non-conductive, which means that wires must be integrated into the robotic hands to transmit electrical signals from sensing systems.

A research team from Singapore and China, led by Prof Chen Xiaodong of NTU’s School of Materials Science and Engineering, has now created an “electro-tendon” from spider silk that resembles human tendons.

In more than 40,000 cycles of bending and stretching, the electro-tendon exhibited considerably higher toughness, durability, flexibility and conductivity than any other material currently available.

“A single electro-tendon fibre enabled our robotic hand to capture fragile objects, such as an inflated balloon, without damaging them, thus eliminating the need for additional wires or circuit components,” says Prof Chen, who is also Director of the Max Planck-NTU Joint Lab for Artificial Senses.

Besides robotics and prosthetics, other potential applications for the electro-tendon fibres include durable anti-static cables as well as electrodes for tough and flexible electronic circuits.

The article “A supertough electro-tendon based on spider silk composites” was published in Nature Communications (2020), DOI: 10.1038/s41467-020-14988-5. The tactile sensitivity of the robotic hand is demonstrated in this video.

.tmb-listing.jpg?Culture=en&sfvrsn=29c7e020_1)

.tmb-listing.jpg?Culture=en&sfvrsn=55153609_1)