Machine learning technique sharpens mechanical property prediction

The new analytical technique could reduce the need for time-consuming and costly computer simulations, to ensure that manufactured parts used in structural applications are safe to use in real-life conditions

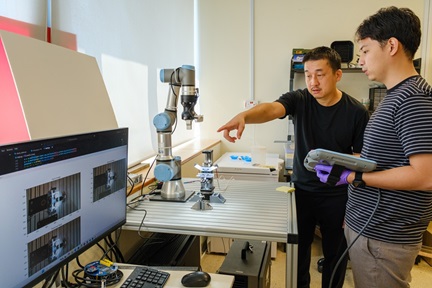

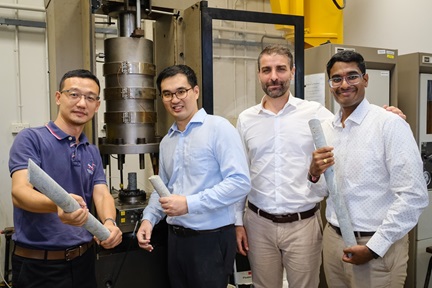

Scientists at NTU Singapore, Massachusetts Institute of Technology (MIT), and Brown University have developed new approaches that significantly improve the accuracy of an important material testing technique by harnessing the power of machine learning.

Nano-indentation – the process of poking a sample of a material with a sharp needle-like tip to see how the material responds by deforming – is important in many manufacturing applications, but its poor accuracy in obtaining certain key mechanical properties of a material, has prevented it from being used widely in industry.

Using the standard nano-indentation process and feeding its experimentally-measured data to a neural network machine learning system, the scientists developed and ‘trained’ the system to predict samples’ yield strength 20 times more accurately than existing methods.

The new analytical technique could reduce the need for time-consuming and costly computer simulations, to ensure that manufactured parts used in structural applications such as airplanes and automobiles, and those made from digital manufacturing techniques such as 3D printing are safe to use in real-life conditions.

The senior corresponding author of this paper, NTU Distinguished University Professor Subra Suresh, who is also the university president, said: “By incorporating the latest advances in machine learning with nano-indentation, we have shown that it is possible to improve the precision of the estimates of material properties by as much as 20 times. We have also validated this system’s predictive capability and accuracy enhancement on conventionally manufactured aluminum alloys and 3D-printed titanium alloys. This points to our method’s potential for digital manufacturing applications in Industry 4.0, especially in areas such as 3D-printing.”

The findings were published in the Proceedings of the National Academy of Sciences of the United States of America today.